Cov Khoom Siv Pcb

Anke PCB muaj ntau txoj kev xaiv find suav nrog cov tshuab xa ntawv yooj yim, xaiv tsa thiab tsis siv neeg lub suab paj nruag thiab tsis siv neeg kom loj thiab tsis siv neeg

Ntawm Anke PCB peb to taub zoo yog lub hom phiaj tseem ceeb ntawm-cov-kos duab vej fais fab kawg thiab kev sib dhos equipments.

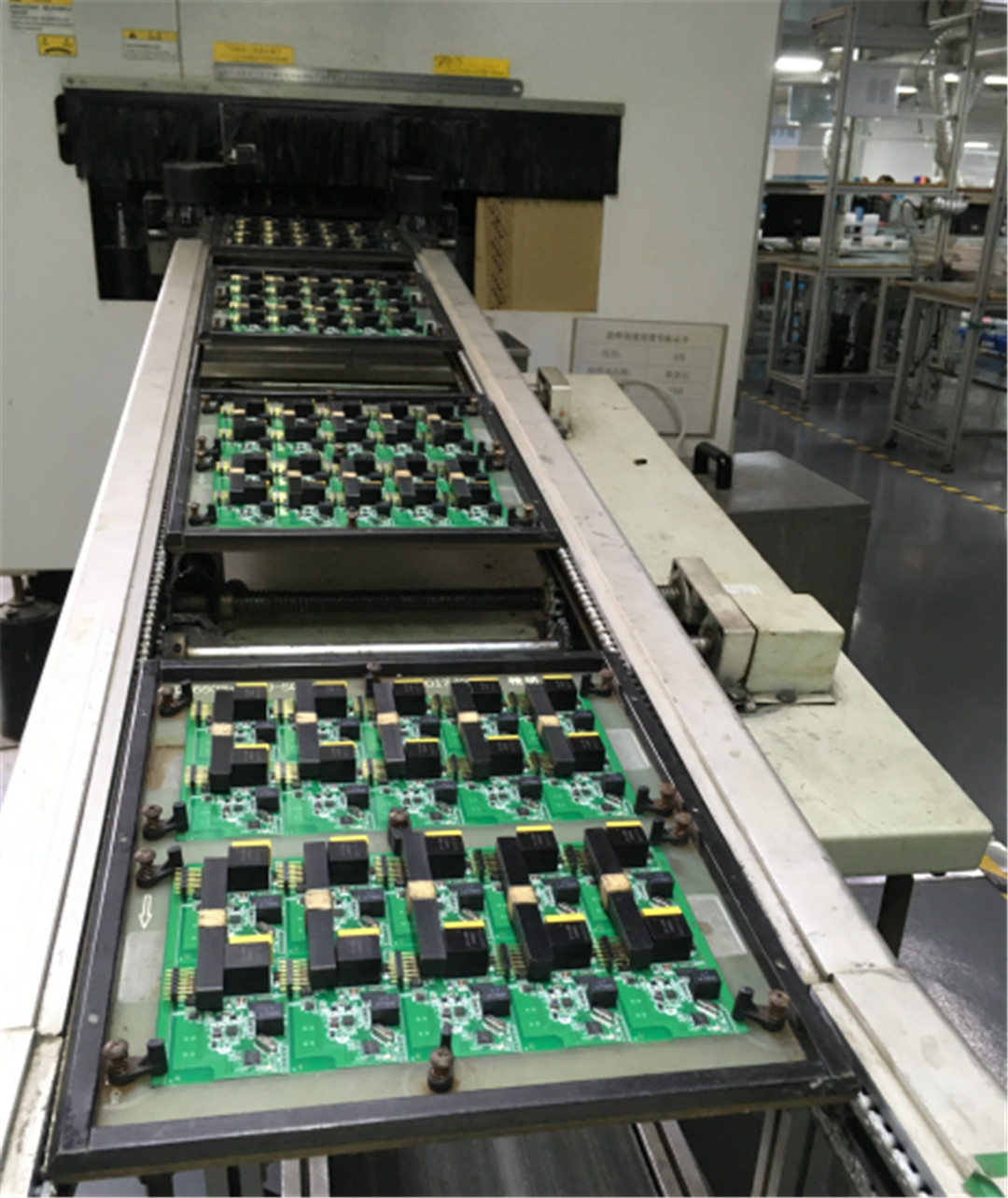

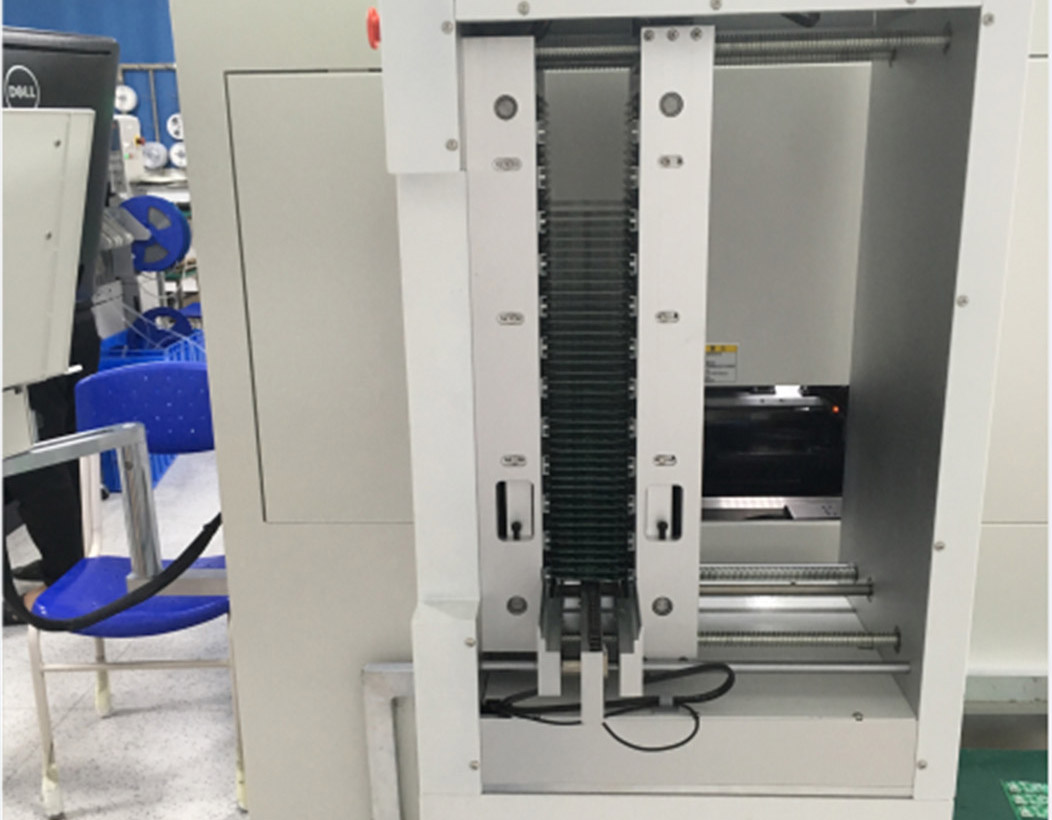

Tsis siv neeg PCB loader

Cov tshuab no tso cai rau PCB cov laug cam los pub rau hauv lub tshuab hluav taws xob tsis siv neeg.

Yam uas pab

• Lub sijhawm txuag rau kev ua haujlwm quab yuam

• NQI RAU HAUV KEV HLAUG

• Txo cov kev ua txhaum uas yuav ua rau los ntawm phau ntawv

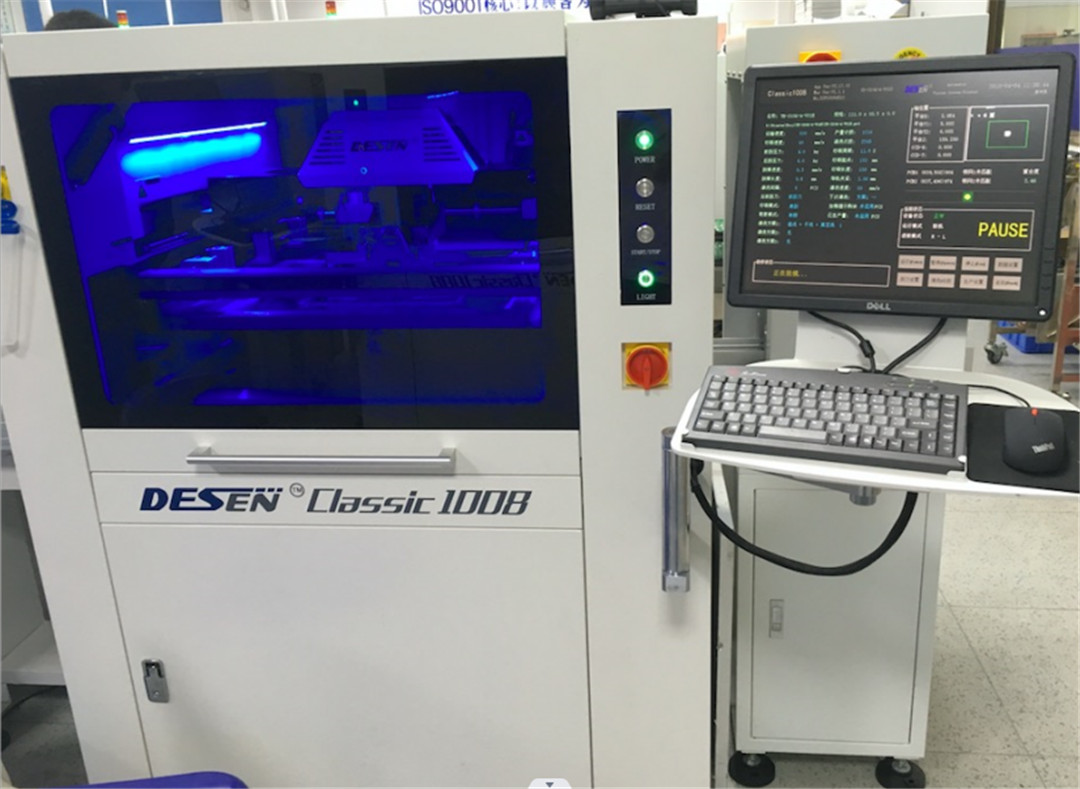

Tsis siv neeg stencil tshuab luam ntawv

Anke muaj cov khoom siv ua ntej xws li tsis siv neeg stencil tshuab luam ntawv machine.

• Programmable

• SqueeGee system

• Stencil tsis siv neeg txoj haujlwm system

• Kev tu kom huv

• PCB hloov mus thiab tso haujlwm

• Yooj yim-siv-siv interface mana kev cai Askiv / Suav

• Duab Daus

• 2nd kev soj ntsuam & spc

• CCD stencil li cas

SMT PU &UM CAV

• Qhov tseeb thiab siab hloov kho rau 01005, 0201, CSIC, QFP, QFP, QF, QF

• Tsis muaj kev sib tiv tauj cov kab mob tawm ntawm cov txheej txheem rau kev rov ua haujlwm siab dua thiab ruaj khov

• Ntsiav tshuaj pub rau cov neeg siv tshuaj pub dua muab cov kev kuaj xyuas kev noj haus tsis siv neeg, cov ntaub ntawv suav ua ib yam, cov ntaub ntawv ntau lawm, cov ntaub ntawv ntau lawm, cov ntaub ntawv ntau lawm, cov ntaub ntawv ntau lawm

• Cognngment System "Lub Zeem Muag Ntawm Ya"

• Lub Zos Dag Zog Txheej Txheem rau Cov Pit Qfp thiab BGA

• Zoo meej rau me & Nruab Nrab Qhov Ntau Lawm

• Ua cov koob yees duab system nrog lub ntsej muag pib farucial kev kawm

• Daim ntawv tso cai xa khoom

• Kev soj ntsuam pom ua ntej thiab tom qab ntau lawm

• Universal Cad Hloov Kev Sib Tham

• Cov Ncej: 10,500 CPH (IPC 9850)

• Pob ntsia ntsia hlau tshuab hauv x- thiab y-axes

• Haum rau 160 cov tswv yim tseem ceeb pib kab xev pub muag

Txhuas dawb reflow cub / txhuas kev ywj pheej soldering soldering tshuab

• Windows XP kev ua haujlwm software nrog Suav thiab Askiv lwm txoj kev xaiv. Tag nrho cov kab ke hauv qab

Kev tswj kev sib xyaw ua ke tuaj yeem txheeb xyuas thiab tso cov tsis ua haujlwm. Txhua cov ntaub ntawv ntau lawm tuaj yeem txuag tag nrho thiab raug txheeb xyuas.

• PC & Siemens plc tswj hwm nrog kev ua haujlwm ruaj khov; Kev precision ntawm profile repetition tuaj yeem zam cov khoom poob ua rau cov txawv txav ntawm lub computer.

• Tus qauv tshwj xeeb ntawm cov thermal convertection ntawm cov chaw cua sov ntawm 4 sab muab kev ua tau zoo kub; Lub siab-qhov sib txawv ntawm 2 thaj chaw sib luag tuaj yeem zam tsis txhob kub ntxhov; Nws tuaj yeem ua kom luv luv qhov kub sib txawv ntawm loj-loj thiab cov khoom me me thiab ua kom tau raws li cov ntawv thov sib dhos ntawm cov PCB nyuaj.

• Yuam kev cua txias lossis dej txias chiller nrog cov cua txias ua kom txias ua kom zoo nkauj txhua yam ntawm cov hmoov txhuas dawb soldering muab tshuaj txhuam.

• Kev siv hluav taws xob tsawg (8-10 kWh / teev) kom txuag tau tus nqi tsim khoom.

AOI (Automated Secvection system)

AOI yog ib lub cuab yeej uas pom tias nquag muaj qhov tsis xws nyob rau hauv vuam kev sib tw ua haujlwm raws kho qhov ntawm cov ntsiab cai kho qhov muag. AOL yog qhov sim thev naus laus zis, tab sis nws tab tom tsim kho kom sai, thiab ntau cov tuam ntxhab tau ua tiav cov khoom siv ntsuas.

Thaum tsis siv neeg tshuaj xyuas, lub tshuab cia li scans pcba los ntawm lub koob yees duab, sau cov duab, thiab muab sib piv cov pob qij txha sib npaug nrog cov qauv tsim nyog hauv cov ntaub ntawv. Kho Vaj Tshab.

Kev nrawm nrawm, lub ntsiab-precision pom kev siv tshuab yog siv los txiav feem ntau qhov chaw muab tsis raug thiab soldering tsis xws ntawm PB Board.

PC cov laug cam ntau los ntawm cov laug cam zoo-ceev-exensity cams rau cov kev daws teeb meem loj loj, muab cov kev tshuaj tiv thaiv kab hauv kev txhim kho ntau thiab cov cai ua tau zoo.

Los ntawm kev siv AOL ua cov cuab yeej txo qis, yuam kev tuaj yeem pom thiab tshem tawm thaum ntxov hauv cov txheej txheem sib dhos, ua rau tswj cov txheej txheem zoo. Ntxov thaum ntxov pom ntawm qhov tsis xws luag yuav tiv thaiv cov laug cam tsis zoo los ntawm kev xa mus rau cov kev sib dhos ua ke. AI yuav txo cov nqi kho thiab zam kom cov menyuam cov laug cam dhau ntawm kev kho.

3D X-Ray

Nrog kev txhim kho kev txhim kho ntawm cov tshuab hluav taws xob, kev sib dhos kom zoo nkauj ntawm ntau qhov kev ua kom zoo nkauj tshiab, thiab kev ua kom zoo dua ntawm cov tshuab hluav taws xob tshiab tau nce qib siab dua thiab siab dua.

Yog li ntawd, cov cai muaj dua yog muab tso rau ntawm txoj kev kuaj pom thiab thev naus laus zis.

Txhawm rau kom tau raws li qhov yuav tsum tau ua, kev tshawb xyuas kev tshawb xyuas tas li, thiab 3D tsis siv neeg Xoo hluav taws xob thev naus laus zis yog ib tus neeg sawv cev raug.

Nws tsis tuaj yeem kuaj pom cov pob qij txha sib tiv thaiv, xws li BGA (pob daim phiaj thiab lwm yam.

Tam sim no, muaj kev sim ntau yam kev sim tshuaj tau thov hauv kev sib dhos hauv tshuab hluav taws xob.

Cov Khoom Siv Hluav Taws Xob feem ntau yog phau ntawv ntsuas kev kuaj xyuas (ICT), thiab tsis siv neeg kho qhov muag

Kev tshuaj xyuas (tsis siv neeg soj ntsuam kev tawm dag zog). AI), tsis siv neeg X-ray soj ntsuam (axi), functional tester (FT) thiab lwm yam.

PCBA chaw nres tsheb

Raws li cov txheej txheem rov ua haujlwm ntawm tag nrho SMT los ua ke muaj kev txhawj xeeb, tivthaiv ntxuav, pcb padwering, page ncoo ntxuav, vuam, thiab tu.

1. Desoldering: Cov txheej txheem no yog kom tshem tawm cov kev kho kom haum los ntawm PB ntawm cov khoom siv ruaj ruaj. Cov txheej txheem yooj yim tshaj plaws tsis yog kev puas tsuaj lossis puas qhov tshem tawm ntawm lawv tus kheej, cov khoom siv ib puag ncig thiab cov ntaub qhwv pcb.

2. Kev sib koom ua ke: tom qab cov khoom siv rov ua haujlwm yog desoldered, yog tias koj xav txuas ntxiv siv cov khoom sib txuas, koj yuav tsum rov kho cov khoom siv.

3. PCB ncoo Tu: PCB ncoo ntxuav ua ke nrog rau kev ua kom huv ncoo thiab cov ua haujlwm tu ua haujlwm. Ncua kev ntsuas feem ntau yog hais txog kev ntsuas ntawm pcb pcb saum npoo ntawm cov ntaus ntawv tshem tawm. Ncoo tu feem ntau siv cov harder. Ib qho cuab yeej tu, xws li cov hlau soldering, tshem cov ntawv so los ntawm kev quav dej cawv lossis cov ntaub ntawv pom zoo kom tshem tawm cov nplua thiab seem flux Cheebtsam.

4. Cov kev tso kawm ntawm cov khoom siv: Tshawb xyuas cov pcb reworkiv nrog cov luam tawm cov khoom siv; Siv cov khoom sib xyaw ua ke ntawm cov chaw nres tsheb ua haujlwm uas tsim nyog nqus hluav taws xob ncau thiab kho cov pcb pcb kom muab tso.

5. SOLDERING: Tus txheej txheem soldering rau cov khoom noj yuav ua tau yooj yim sib faib hauv kev tuav cov lus thiab ua kom sib zog sib zog. Yuav tsum tau txais kev txiav txim siab ua tib zoo saib raws li cov khoom sib xyaw thiab cov qauv PB, ntxiv rau cov khoom siv vuam siv. Kev tuav cov ntaub ntawv vuam yog qhov yooj yim thiab yog siv rau kev ua haujlwm vuam ntawm qhov chaw me me.

Lead-Free WOW SOLDERING TSHUAB

• Kov npo + Plc tswj chav, yooj yim thiab txhim khu kev qha.

• Cov qauv tsim yooj yim sab nraud, cov qauv tsim hauv cov qauv tsim, tsis yog zoo nkauj xwb tab sis kuj yooj yim tswj.

• Cov tshuaj tsuag tshuaj txau flux flux ua tau zoo atomization zoo nrog cov tshuaj flux noj tsawg.

• Turbo kiv cua tso tawm nrog daim ntaub ntaub thaiv kom tiv thaiv cov diffusion ntawm atomized flux rau hauv thaj chaw preheating, kom muaj kev nyab xeeb.

• Modularized rhaub preheating yog yooj yim rau kev saib xyuas; Pid tswj cua sov, ruaj khov, du nkhaus, daws cov teeb meem ntawm cov txheej txheem pub dawb.

• Cov lauj kaub khi uas muaj lub zog, tsis yog deformable hlau tsim ua hluav taws xob zoo dua ua haujlwm ua haujlwm.

Nozzles ua los ntawm titanium kom muaj kev deformation tsawg thiab oxidation tsawg.

• Nws muaj txoj haujlwm ntawm automatic lub sijhawm pib thiab kaw ntawm tag nrho cov tshuab.