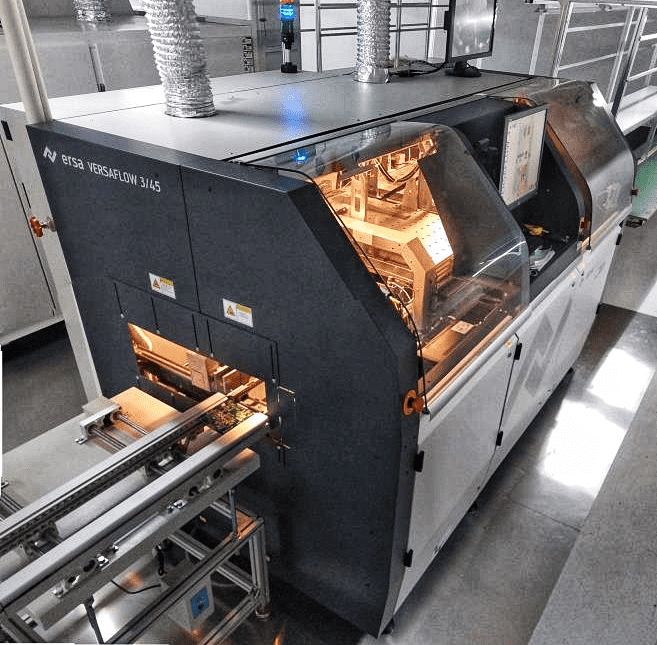

In Pcbasoldering txheej txheem, lub soldering ntawmPlug-incalentsntawm PCBA feem ntau cuam tshuam nrog soldering soldering lossis ib txwm siv nthwv dej soldering, uas tau nkag siab tsis txhob muaj saum npoo-mountedSmtCov ntaub ntawv thiab qee yam tsis yog-tinned los ntawm qhov, xav tau kev txheeb xyuas ntawm soldering suptures. Qhov no ua rau cov nqi fixture ntxiv, nce solder siv nyiaj ntau dua vim muaj kev siv zog tin thaj chaw, thiab muaj kuab paug siab. Tshwj xeeb tshaj yog nyob rau hauv kev daws cov kev cov nyom ntawm kev tsim cov khoom me me nrog ntau yam khoom lag luam, lub sijhawm tsim nyog rau fixture Fabrication yog qhov nyuaj tau ntsib. Txhawm rau kom ua tiav cov lus cog tseg rau kev ua tau zoo thiab ua tau zoo, muaj tub rog, AERA VERSIONSE rau cov khoom lag luam Higha Cov tshuab no kom huv si thiab txo cov teeb meem dhau los, txhim kho kev ua haujlwm, kev ntseeg tau zoo, thiab kev ruaj ntseg ntawm cov khoom siv soldered.

Piv rau ib txwm muaj cov cua soldering, cov khoom siv no muaj cov yam ntxwv ua hauv qab no:

● Tsis siv neeg adaptation rau PCB

Raws li kev sib koom tes ntawm MES system, nws tuaj yeem hu tau qhov kev pab cuam vuam los ntawm QR code lees paub ntawm cov cim pcb txawv, thiab ua tiav online hloov;

● Ntau qhov zoo tshaj plaws

ERSA EVUITY YOJ SOLDERING muab cov vuam zoo - cov khoom ruaj khov thiab kev ntseeg tau yuav ncav cuag 99.999%. Nws cia li hu rau lub Preset Vuam txoj haujlwm kom ua tiav kev hloov kho online thiab cov kev sib txawv ntawm cov vuam cov kev yuav tsum muaj cov kev sib txawv. Qhov no tshem tawm cov cuab yeej overheating overheating thiab ua kom muaj kev ua kom nruj bridging lossis voids, ua rau muaj kev lom zem solder pob qij txha pob qij txha.

Txo solder noj

Cov tshuaj yetental yuav tsum muaj cov lus nug nyuaj ntawm ntau dua 400kg, thiab cov solder xav tau txuas ntxiv melted thiab ntxhov siab, h ntawm solder dross pov tseg. Nyob rau hauv kev sib piv, ersa tsuas yog xav tau cov lus nug soldering ntawm 10kg ib da dej, tsim tsuas yog kwv yees li 2kg ntawm solder dross hauv ib hlis. Thaum lub sij hawm soldering txheej txheem, cov cam cov hlau yog tiv thaiv los ntawm 99.999% cov pob qij txha, ua kom cov pob qij txha ua kom tau siv rau ntawm cov cam dross. Cov yeeb yam no tsis tsuas yog ua kom cov kev nyiam huv ntawm cov soldering nto tab sis kuj txhim kho qhov zoo thiab cuam tshuam nrog kev siv solding.

● Ntau lub zog-txuag thiab ib puag ncig phooj ywg

ERSA EVUCTIONS YEEB YOOJ YIM SOLDERING TSHUAB hluav taws xob yog siv hluav taws xob tsuas yog 12kW tsuas yog 12kW, uas yog 1/4 ntawm Wave Videdering. Ersa kev xaiv yoj soldering tshem tawm cov kev xav tau lub sijhawm siv sijhawm thiab cov nqi tshwj xeeb fixtures rau kev siv cov yoj sib xyaw. Lub centrally headly heeded solder da dej da dej thiab sib qab tsis siv neeg preheating txo kev siv hluav taws xob los ntawm kwv yees li 25%. Lub autated pind txau txoj kev sib txaws sib xyaw rau cov pob qij txha sib npaug los ntawm kev siv cov pa hluav taws xob los ntawm 80% thiab ntau dua pcb tu cov txheej txheem los ntawm kwv yees li 70%.

Tom qab kev taw qhia thiab commissioning ntawm German ersa xaiv yoj schering system, xws li cov khoom sib txuas ua ke, thiab lwm yam) tau nce ntawm 91.3% rau 99.9%. This has greatly addressed the quality risks and potential hazards in this critical process, providing solid and sufficient guarantee for the soldering reliability and stability of customers' high-end products. Nws pab txhawb kev hloov sai sai thiab kev txhim kho rau cov khoom lag luam muag khoom thiab tseem pom zoo ntawm cov khoom lag luam.

Shenzhen Anke PCB Co., Ltd

2023-8-22

Lub sij hawm Post: Aug-23-2023