Nrog kev hloov pauv sai ntawm lub neej tam sim no uas yuav tsum tau siv ntau dua cov txheej txheem ntawm koj cov kev xav tau zoo rau kev txhim kho cov thev naus laus zis tshiab kom tau raws li cov neeg siv cov kev xav tau.

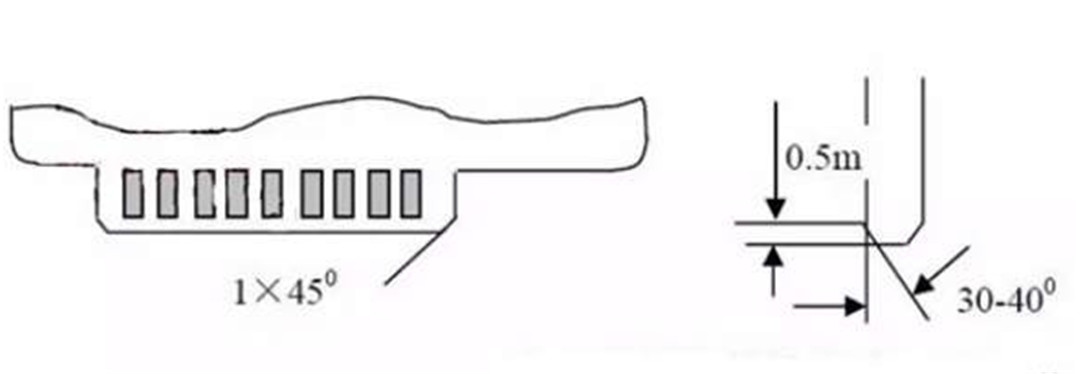

Ntug txuas bevelling rau cov ntiv tes kub

Ntug Txuas Bevelling feem ntau siv nyob rau hauv kub ntiv tes rau kub plated cov laug cam lossis enig laug cam, nws yog qhov txiav lossis ntawm ntug txuas ntawm ib lub kaum sab xis. Tej beveled txuas pci lossis lwm yam ua rau nws yooj yim dua rau pawg thawj coj mus rau hauv qhov txuas. Ntug Txuas Bevelling yog ib qho parameter nyob rau hauv cov lus txib cov ntsiab lus uas koj xav tau xaiv thiab tshawb xyuas qhov kev xaiv no thaum xav tau.

Carbon Sau

Cov thawv luam tawm yog ua los ntawm cov number teb carbon thiab tuaj yeem siv rau cov neeg sib tiv toj, LCD cov neeg hu thiab dhia dhia. Kev luam ntawv tau ua nrog cov number cason number cask.

Cov pa roj carbon hais yuav tsum tawm tsam soldering lossis hal.

Rwb thaiv tsev lossis carbon dav yuav tsis txo qis dua 75% ntawm tus nqi nominal.

Qee lub sij hawm lub ntsej muag tshiab yog qhov tsim nyog los tiv thaiv siv cov hmoov.

PUAB YEEDS SOLDERMASS

Peel tau soldermask Cov peelable tiv thaiv txheej yog siv los npog thaj chaw uas tsis yog siv cov txheej txheem yoj yoj. Txheej hloov tau yooj yim no tau muab tshem tawm tau yooj yim rau cov yeeb yam zoo meej rau cov txheej txheem sib dhos los ntawm cov txheej txheem sib dhos.

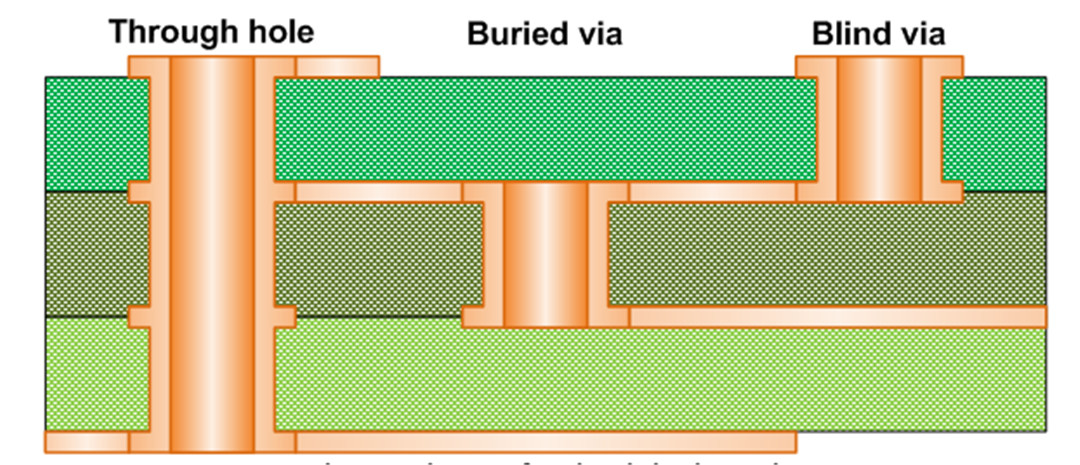

Dig Muag & Buried Vais

Dab tsi yog qhov muag tsis pom kev?

Hauv ib qho dig muag ntawm, lub ntawm txuas rau sab nraud txheej sab nraud rau ib lossis ntau dua sab hauv tus PCB thiab lub luag haujlwm rau kev sib txuas lus nruab nrab thiab cov khaubncaws sab nraud povtseg.

Dab tsi yog faus ntawm?

Nyob rau hauv ib tug faus ntawm, tsuas yog cov khaubncaws hauv paus sab hauv ntawm lub rooj tsavxwm tau txuas nrog los ntawm. Nws yog "faus" hauv Board thiab tsis pom ntawm sab nraud.

Qhov muag tsis pom thiab cov lus dig muag tau muaj txiaj ntsig zoo tshaj plaws nyob rau hauv HDI cov laug cam vim tias lawv ua kom zoo rau pawg ceev tsis muaj nce txheej txheem pawg yuav tsum tau ua.

Yuav ua li cas ua kom dig muag & faus vias furied

Feem ntau peb tsis siv qhov tob-tswj laser drilling los tsim cov dig muag thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab faus vias thiab furied vias. Firstly peb tho ib lossis ntau lub cores thiab phaj los ntawm lub qhov. Tom qab ntawd peb tsim thiab nias cov pawg. Txoj kev no tuaj yeem rov ua dua ob peb zaug.

Qhov no txhais tau tias:

1. Ib qho ntawm ib txwm yuav tsum tau txiav los ntawm ib tus naj npawb tooj liab los.

2. Ib qho ntawm tsis tuaj yeem xaus rau sab saum toj ntawm ib qho tseem ceeb

3. Ib qho ntawm tsis tuaj yeem pib hauv qab sab ntawm ib qho tseem ceeb

4. Qhov muag tsis pom kev tsis tuaj yeem pib lossis xaus rau sab hauv lossis lwm qhov muag tsis pom kev (qhov no yuav ntxiv cov nqi ntxiv uas yuav tsum tau ua dua tshiab).

Kev Cuam Tshuam Tswj

Kev tswj kev tsis sib haum xeeb tau yog ib qho ntawm cov kev txhawj xeeb tseem ceeb thiab cov teeb meem loj hauv cov qauv nrawm nrawm.

Hauv cov ntawv thov siab ntau, tswj kev yuam yuav pab peb xyuas kom meej tias cov cim tsis yog degraded raws li lawv txoj kev ncig pcb.

Kev tawm tsam thiab cov tshuaj tiv thaiv hluav taws xob muaj qhov cuam tshuam loj rau kev ua haujlwm, raws li cov txheej txheem tshwj xeeb yuav tsum ua tiav ua ntej lwm cov kev ua haujlwm kom raug.

Qhov tseem ceeb, tswj kev cuam tshuam yog qhov txuam ntawm substrate cov khoom siv nrog cov kab ke ntawm ib qho feem pua ntawm ib qho nqi tshwj xeeb.