Khoom

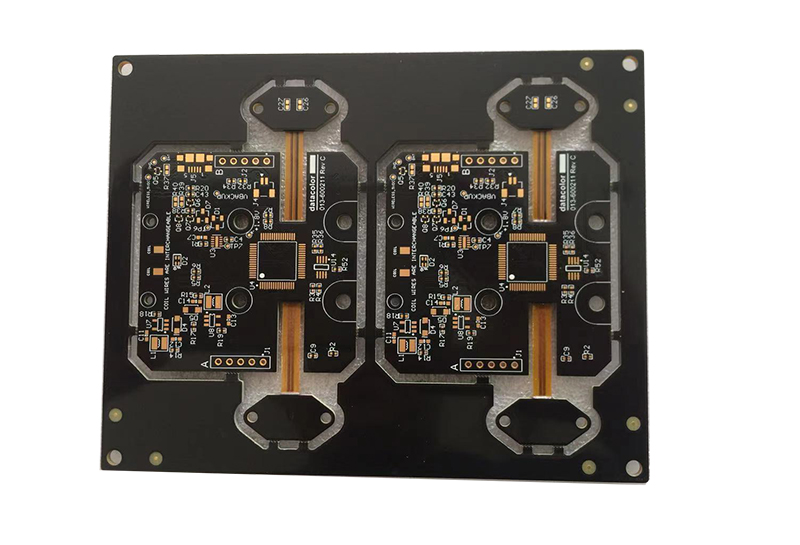

Kev lag luam sensor 4 Txheej Rigid & Flex PCB nrog 2oz Tooj

| Txheej | 4 txheej rigid + 2 txheej flex |

| Board Thickness | 1.60mm + 0.2 hli |

| Khoom | Fr4 tg150 + polymide |

| Tooj liab Thickness | 1 oz (35um) |

| Nto tas | Enig au thickness 1um; Ni thickness 3um |

| Min Qhov (MM) | 0.21mm |

| Min kab dav (hli) | 0.15 hli |

| Min kab chaw (hli) | 0.15 hli |

| Taus Daim Npog | Xim ntsuab |

| Cov lus dab neeg xim | Xim dawb |

| Ua Txhua Yam | V-Quav, CNC Milling (kev coj) |

| Yam ntim | Anti-static lub hnab |

| E-xeem | Flying spare lossis fixture |

| Txais Qauv | IPC-A-600H chav kawm 2 |

| Daim ntawv thov | Automotive Electronics |

Lub hauv paus rau phau ntawv

Rigid & Flex PCBs tau sib koom ua ke nrog cov khoom txhav txhav txhawm rau tsim cov khoom lag luam zoo nkauj no. Qee txheej ntawm cov txheej txheem tsim khoom lag luam suav nrog Circuit Court siv tau yooj yim uas sau los ntawm cov laug cam rigid, zoo li

Tus txheem hardboard puag ncig tsim.

Cov thawj coj tsim qauv yuav ntxiv plated los ntawm qhov (pths) uas hloov txhav thiab hloov hluav taws xob ua ib feem ntawm cov txheej txheem no. Cov PCB no tau nrov vim nws txoj kev txawj ntse, qhov raug, thiab yoog raws.

Rigid-Flex PCBs Yooj Yim Tsim Kho Hluav Taws Xob los ntawm kev tshem cov cables hloov tau, kev sib txuas, thiab cov xaim uas tus kheej. Ib txoj hlua khi & FLEX Boards Circuitry tau nruj dua rau hauv Pawg Thawj Coj Txheej Txheem, uas txhim kho kev ua haujlwm hluav taws xob.

Cov kws tsim khoom lag luam tuaj yeem tau txais qhov kev ua tau zoo thiab hluav taws xob ua tsaug rau qhov tsis muaj hluav taws xob thiab cov tshuab sib txuas.

Khoom

Substrate Cov Ntaub Ntawv

Cov tshuaj nyiam tshaj plaws ntawm cov tshuaj tua hluav taws xob yog woven fiberglass. Ib txheej tuab ntawm Epoxy Resin tsho no cov fiberglass.

Txawm li cas los xij, Epoxy-impregnated fiberglass yog tsis paub tseeb. Nws tsis tuaj yeem tiv taus rau kev poob siab thiab txhawb nqa kev poob siab.

Polyimide

Cov ntaub ntawv no yog xaiv rau nws qhov yooj. Nws yog khoom khov thiab tuaj yeem tiv taus kev poob siab thiab cov lus tsa suab.

Polyimide tseem tuaj yeem tiv thaiv kom sov. Qhov no ua rau nws zoo tagnrho rau cov ntawv thov nrog cov kev hloov pauv hloov pauv.

Polyester (Tsiaj)

Tsiaj yog favored rau nws cov yam ntxwv hluav taws xob thiab hloov tau. Nws resistics tshuaj lom neeg thiab dampness. Nws yuav yog li ua haujlwm hauv kev muaj cov xwm txheej hnyav.

Siv ib qho kev tsim nyog substrate ua kom muaj zog xav tau lub zog thiab ntev. Nws txiav txim siab zoo li kub ua rau thiab qhov loj me thaum xaiv ib substrate.

Polyimide Cov Khoom Txhuas

Qhov ntsuas kub ntawm cov nplaum no ua rau nws zoo tagnrho rau txoj haujlwm. Nws tuaj yeem tiv taus 500 ° C. Nws cov cua sov siab ua rau nws haum rau ntau cov ntawv thov tseem ceeb.

Cov nplaum Polyester

Cov nplaum no muaj nqi ntau dua tshaj li cov nplaum nplaum polyimide.

Lawv zoo heev rau kev ua kom yooj yim ua kom nruj cov ntawv pov thawj.

Lawv txoj kev sib raug zoo kuj tsis muaj zog. Polyester cov nplaum tseem tsis yog cov tiv thaiv kub. Lawv tau raug hloov kho tsis ntev los no. Qhov no muab rau lawv nrog kub ua hauj. Qhov kev hloov no tseem txhawb nqa kev yoog. Qhov no ua rau lawv muaj kev nyab xeeb hauv multilayer pcb los ua ke.

Cov Khoom Siv Acrylic

Cov nplaum no yog qhov zoo dua. Lawv muaj cov thermal zoo rau kev tiv thaiv xeb thiab tshuaj lom neeg. Lawv yooj yim thov thiab pheej yig. Ua ke nrog lawv muaj, lawv tau nrov ntawm cov tuam ntxhab. cov tuam txhab tsim.

Epoxies

Qhov no yog tej zaum cov nplaum tshaj plaws hauv cov nplaum hauv cov nplaum hauv qhov chaw ua kom nruj-flex. Lawv kuj tseem tuaj yeem tiv taus corrosion thiab siab thiab qis kub.

Lawv kuj tseem yoog tau thiab ruaj khov ruaj khov. Nws muaj me ntsis polyester hauv nws uas ua rau nws yoog tau.

Pawg-up

Cov pawg-up ntawm rigid-ex pcb yog ib qho ntawm feem ntau qhov chaw thaum lub sij hawm

Rigid-Ex pcb fabrication thiab nws nyuaj dua li tus qauv

Rigid cov laug cam, cia peb saib 4 txheej ntawm rigid-ex pcb raws li hauv qab no:

Sab saum toj Taus Daim Npog

Sab saum toj txheej

Dielectric 1

Teeb Liab Txheej 1

Dielectric 3

Teeb Liab Txheej 2

Dielectric 2

Hauv qab txheej

Hauv qab Symask

Tus Pej Xeem PcB

| Rigid Board muaj peev xwm | |

| Tus naj npawb ntawm cov khaubncaws sab nraud povtseg: | 1-42 txheej |

| Khoom siv: | Fr4 \ High TG FR4 \ Lead Cov Khoom Siv Dawb \ Cem1 \ Cem3 \ Aluminium Core Hlau \ PTFE \ Rogers |

| Tawm txheej CU Thickness: | 1-6oz |

| Sab hauv txheej CU Thickness: | 1-4oz |

| Qhov chaw ua ntau tshaj plaws: | 610 * 1100mm |

| LAZES tsawg kawg board thickness: | 2 txheej 0.3mm (12mil) 4 txheej 0.4mm (16mil)6 txheej txheej 0.8mm (32mil) 8 txheej 1.0 hli (40mil) 10 txheej txheej 1.1mm (44mil) 12 txheej 1.3mm (52mil) 14 txheej 1.5 hli (59mil) 16 txheej 1.6mm (63mil) |

| Qhov dav tsawg kawg: | 0.076mm (3mil) |

| Chaw tsawg kawg nkaus: | 0.076mm (3mil) |

| Qhov tsawg kawg nkaus qhov loj me (kawg lub qhov): | 0.2 hli |

| Nam natio: | 10: 1 |

| Drilling Qhov Loj: | 0.2-0.65mm |

| Drilling Daus: | + \ - 0.05mm (2mil) |

| PTH DOLANCE: | Φ0.2-1.6mm + \ - 0.075mm (3mil) Φ1.6-6.3mm + \ - 0.1mm (4mil) |

| NPH kam rau: | Ill0.2-1.6mm + \ - 0.05mm (2mil) Φ1.6-6.3mm + \ - 0.05mm (2mil) |

| Tiav Board Divilance: | Thickness <0.8mm, kev ua siab ntev: +/- 0.08mm |

| 0.8mmmmncskness≤6.5 hli, Tunorance +/- 10% | |

| Yam tsawg kawg nkaus Soldergask Choj: | 0.076mm (3mil) |

| Sib ntswg thiab dabtsi yog khoov: | I≤0.75% Min0.5% |

| Raneg ntawm tg: | 130-215 ℃ |

| Impedance kam rau: | +/- 10%, min +/- 5% |

| Nto Kho: | HASL, LF HASL |

| Immersion kub, nyem kub, kub ntiv tes | |

| IPCIERS NYIAJ TXIAS TXIAS TXIAS TXIAS TXIAS TXIAS TXIAS, osp | |

| Xaiv Nyiaj Kub Plating, Kub Thickness Txog 3um (120U ") | |

| Cov pa roj carbon prin, potable s / m, enepig | |

| Aluminium Board Muaj Peev Xwm | |

| Tus naj npawb ntawm cov khaubncaws sab nraud povtseg: | Ib Leeg, Ob Chav |

| Cov Thawj Coj Ntau Tshaj: | 1500 * 600 hli |

| Board Thickness: | 0.5-3.0 hli |

| Tooj liab Thickness: | 0.5-4oz |

| Qhov tsawg kawg qhov loj me: | 0.8mm |

| Qhov dav tsawg kawg: | 0.1mm |

| Chaw tsawg kawg nkaus: | 0.12mm |

| Qhov tsawg kawg nkaus ncoo loj: | 10 Micron |

| Deg tas: | HASL, osp, ENIG |

| Daim Duab: | CNC, xuas nrig ntaus nrig, V-txiav |

| Equipement: | Universal Tester |

| Flying Sparee Qhib / Cov Lus Qhia Leeb | |

| High fais fab tsom | |

| Soldering Saitary Kuaj Cov Khoom Siv | |

| TUAM LUB LAWM TESTER | |

| Lub Fig Volt Xauj & Cov Tester Luver | |

| Hla ntu Moulding Cov Khoom Siv nrog Polisher | |

| FPC Peev Xwm | |

| Txheej ( | 1-8 Txheej |

| Board Thickness: | 0.05-0.5mm |

| Tooj liab Thickness: | 0.5-3oz |

| Qhov dav tsawg kawg: | 0.075mm |

| Chaw tsawg kawg nkaus: | 0.075mm |

| Hauv qhov loj me: | 0.2 hli |

| Yam tsawg kawg nkaus Laser Qhov Loj: | 0.075mm |

| Yam tsawg kawg nkaus punching qhov loj me: | 0.5mm |

| SoldMask hwm: | + \ - 0.5 hli |

| Qhov tsawg kawg nkaus cov kev coj dimchaw: | + \ - 0.5 hli |

| Deg tas: | HASL, LF HASL, ITItry Nyiaj, IMIPATION KUB kub, Nyem kub, osp |

| Daim Duab: | Xuas nrig ntaus, laser, txiav |

| Equipement: | Universal Tester |

| Flying Sparee Qhib / Cov Lus Qhia Leeb | |

| High fais fab tsom | |

| Soldering Saitary Kuaj Cov Khoom Siv | |

| TUAM LUB LAWM TESTER | |

| Lub Fig Volt Xauj & Cov Tester Luver | |

| Hla ntu Moulding Cov Khoom Siv nrog Polisher | |

| Rigid & Flex Peev Xwm | |

| Txheej ( | 1-28 Txheej |

| Hom Khoom: | F-4 (High TG, Halogen Free, loj zaus) PTFE, BT, Getek, puag, tooj, Nananya, utter, ilm, Nelco, Rogers, Arlon |

| Board Thickness: | 6-240mil / 0.15-6.0 hli |

| Tooj liab Thickness: | 210um (6oz) rau sab hauv txheej 210um (6oz) rau txheej sab nraud |

| Hnab Nkhaus Laum Loj: | 0.2mm / 0.08 " |

| Nam natio: | 2: 1 |

| Max vaj huam sib luag loj me: | Sigle sab lossis ob sab: 500mm * 1200mm |

| Cov khaubncaws sab nraud multilayer: 508mm x 610mm (20 "x 24") | |

| Min kab dav / chaw: | 0.076mm / 0.076mmm (0.003 "/ 0.003") / 3mil / 3mil |

| Ntawm qhov hom: | Dig muag / faus / ntsaws (VOP, VIP ...) |

| HDI / microvia: | Tau |

| Deg tas: | HASL, LF HASL |

| Immersion kub, nyem kub, kub ntiv tes | |

| IPCIERS NYIAJ TXIAS TXIAS TXIAS TXIAS TXIAS TXIAS TXIAS, osp | |

| Xaiv Nyiaj Kub Plating, Kub Thickness Txog 3um (120U ") | |

| Cov pa roj carbon prin, potable s / m, enepig | |

| Daim Duab: | CNC, xuas nrig ntaus nrig, V-txiav |

| Equipement: | Universal Tester |

| Flying Sparee Qhib / Cov Lus Qhia Leeb | |

| High fais fab tsom | |

| Soldering Saitary Kuaj Cov Khoom Siv | |

| TUAM LUB LAWM TESTER | |

| Lub Fig Volt Xauj & Cov Tester Luver | |

| Hla ntu Moulding Cov Khoom Siv nrog Polisher | |